Robot Controller Solution Based on RK3588J

This robot controller solution is an ideal choice for medium and large-sized robots, suitable for charging robots, cleaning robots, AGVs/AMRs, etc. It integrates cutting-edge technologies, leveraging the ASL architecture and ROS/ROS1 to rapidly deploy the SLAM algorithm for precise environmental perception. The high-performance hardware, combined with advanced voice algorithms, enables sensitive sound pickup and smooth interaction. Its multi-core heterogeneous technology ensures rapid system response, effortlessly handling complex tasks and comprehensively facilitating the efficient operation of robots.

- IO interface: DI,DO,AI, PWM, isolation

- Network port: 1 10/100/1000Mbps Ethernet interface

- Power supply: DC power supply voltage range 9~16VDC

- Operating temperature: -40℃ ~ 85℃

- Cooling Solution: Support radiator

With multi-architecture and diverse technology applications, it offers flexible interactive control

The VCU component of the robot controller is based on the RK3588J chip, integrating an octa-core CPU and a powerful NEON coprocessor. The built-in NPU can perform mixed operations with various integers and floating-point numbers, providing a computing power of up to 6 TOPS.

Perception (SLAM + Voice Interaction)

- It supports the Android Subsystem for Linux (ASL) architecture and has ROS/ROS1 built-in, enabling the rapid transplantation of the SLAM algorithm.

- It supports a 2x8CH digital microphone array, an AI NPU noise reduction algorithm, sound pickup optimization, sound pickup howling suppression, voice wake-up, keyword recognition and other voice algorithm support.

Human - Machine Interaction

- Equipped with an 8 – core CPU, a G610 MP4 GPU, and a 6TOPS NPU.

- Supports MIPI/Type C/eDp/HDMI video output, enabling seamless connection to various display devices.

- Capable of driving 7 – screen independent displays, providing diverse visual interaction options.

Mobile Control

It supports AMP multi – core heterogeneous architecture, allowing human – machine interaction (Android/Linux) and the mobile control system (RTOS) to operate simultaneously. The system can achieve microsecond – level interrupt response latency, meeting the strong real – time and high – stability requirements of robot applications.

Convenient Secondary Development, Hassle - free Algorithm Transplantation, and Adaptability to Diverse Scenarios

Abundant Interfaces

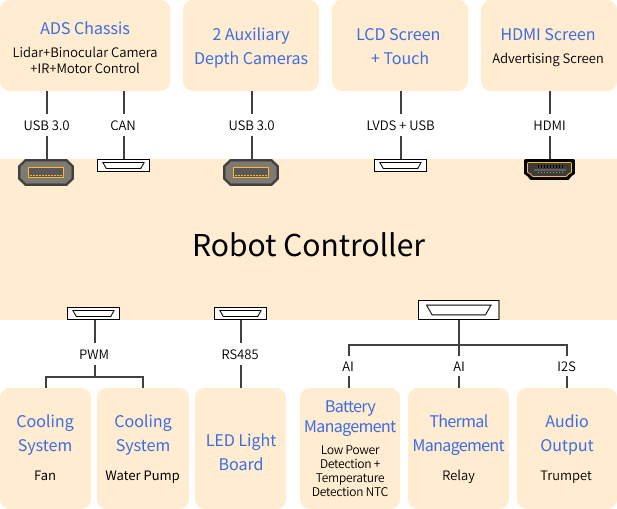

Antek robot controllers offer a wide range of interfaces, supporting diverse robotic applications.

Reliable Components

Connectors are highly reliable, with a robust design for harsh environments and extended lifespan.

EMC Standard Design

Controllers are designed to meet EMC standards, ensuring stable performance in complex environments.

Convenient Secondary Development

Antek provides a user-friendly development environment, rich APIs, and technical support to enhance development efficiency.

Professional Certification

Our team is proficient in global standards like CE and FCC, enabling quick certification and market access.

Accurate Algorithm Transplantation

Our technical team optimizes and adapts algorithms, ensuring intelligent and precise robot operation.

One Stop OEM/ODM Services

ACCELERATE YOUR IOT GATEWAY LAUNCH FROM CONCEPT TO PRODUCTION

Professional R&D Capability, High Quality and Quick Response

Professional R&D

- Over 100 professionals with extensive IoT expertise.

- Efficient collaboration between R&D and production.

- Core algorithms and high versatility in industry-specific chip integration.

- Stable and reliable solutions reducing project R&D risks.

Rapid Manufacturing

- Streamlined design, manufacturing, and quality control. Shortened time-to-market and reduced development costs.

- 30 wave soldering lines, 8 testing lines, and 10 finished product assembly lines. Daily production capacity of 10,000 units.

- MES digital management system with unique QR code for each product.

Supply Chain Management

- Long-term partnerships with multiple mainstream chip manufacturers.

- Keeping abreast of technological advancements.

- Mature production lines ensuring fast and stable delivery.

- Lead times: 4 weeks for small batches (≤1,000 units), 2 weeks for baseline products (≤50 units).

Quality Assurance

- Certified to ISO14001:2015, ISO9001:2015, IATF16949:2016, and ISO45001:2018.

- Product testing includes DQA testing and laboratory certification.

- Utilization of quality management tools: FMEA, PPAP, ECN, SPC/CPK.

Professional R&D Capability, High Quality and Quick Response

Robot Controller FAQs

The core component of the Antek robot controller is based on the RK3588J chip. This chip integrates an octa-core CPU, a powerful NEON coprocessor, and a built-in NPU that can perform mixed operations with various integers and floating-point numbers. These components work in tandem. The CPU is responsible for handling regular computing tasks, the NEON coprocessor accelerates media and signal processing, and the NPU focuses on deep learning and edge computing. Together, they achieve a computing power of up to 6 TOPS, providing the device with strong processing performance.

The Antek robot controller performs excellently in EMC (Electromagnetic Compatibility) standard design. Our R&D team is proficient in international EMC standards. Every aspect, from circuit layout, shielding design to filtering treatment, has been meticulously refined. Through advanced simulation technology, electromagnetic interference issues are predicted and optimized in advance, ensuring that the controller can still operate stably in complex electromagnetic environments, such as industrial production workshops and intelligent warehousing and logistics centers, without signal interruptions, data errors, and other situations, thus guaranteeing the continuity and accuracy of robot operations.

The Antek robot controller provides customers with an extremely convenient secondary development environment. We have opened up a wealth of API interfaces, accompanied by detailed development documents and sample codes. Whether customers have simple function expansion requirements or need to carry out complex system customization, they can easily get started. The professional technical support team is on standby at all times and can promptly answer the questions that customers encounter during the secondary development process, greatly shortening the development cycle, reducing development costs, and helping customers quickly transform their ideas into actual product functions.

The Antek robot controller adopts an aluminum alloy structure. This material has good durability and heat dissipation performance. At the same time, the device is also equipped with a cooling system to ensure stable operating temperature during high-intensity computing. The sturdy metal shell and effective heat dissipation design jointly enhance the durability and stability of the controller, enabling it to work reliably in various environments.

The Antek robot controller is designed according to industrial standards, with an operating temperature range of -40°C to 85°C. This means that it can work normally in extremely cold or hot environments. The sturdy metal shell further enhances its reliability in harsh conditions, making this controller an ideal choice for various industrial application scenarios.

The Antek robot controller supports a variety of video output interfaces, such as HDMI, LVDS, and USB DP, etc., and also supports dual-channel audio output. The design of these multimedia interfaces aims to enhance the user experience, enabling users to easily connect various audio and video devices through the master controller and enjoy a high-quality audio-visual experience.

The rod-shaped antenna design of the Antek robot controller is aimed at optimizing wireless performance, ensuring that the device can maintain a stable wireless connection even in complex environments. The rod-shaped antenna has better directivity and gain performance, and can more effectively receive and transmit wireless signals, thereby improving the wireless communication stability and coverage of the robot controller.

The Antek robot controller adopts a sturdy metal shell and an industrial standard design, with an operating temperature range of -40°C to 85°C, and can be used in harsh conditions. Its stable performance ensures reliable operation in various environments. In terms of hardware design, electronic components that are resistant to high temperature and moisture-proof, as well as a shell with good sealing and heat dissipation, are used to ensure normal operation in high-temperature and high-humidity environments. For strong electromagnetic interference, through shielding technology, a metal shielding cover is used to isolate external electromagnetic signals, and the internal circuit is reasonably wired to reduce electromagnetic coupling. In terms of software, anti-interference algorithms are added, and the sensor data is filtered to remove interference signals, ensuring that the controller can accurately receive and process signals in harsh environments and operate reliably.

In the face of customers’ diverse algorithm requirements, Antek demonstrates strong algorithm transplantation ability. Our technical team is proficient in a variety of mainstream algorithm languages and can quickly understand and adapt to various complex algorithms. Whether it is a visual recognition algorithm, a path planning algorithm, or other cutting-edge algorithms, they can all be accurately transplanted onto our robot controller. By optimizing the adaptation between the algorithm and hardware resources, the performance advantages of the controller are fully utilized, ensuring that the algorithm operates efficiently and stably in practice, providing a solid support for the robot to perform more intelligent and accurate operations.

In terms of the reliability design of the connectors, Antek has invested a great deal of effort. We select high-quality connector materials and conduct strict aging tests, plugging and unplugging life tests, and environmental adaptability tests. The unique structural design enhances the stability of the connectors, effectively resisting the impact of harsh environments such as vibration, shock, and humidity. Whether it is frequent device connection and disconnection or use in special scenarios such as outdoors, high temperature, and high humidity, the connectors can maintain good electrical connection performance, reducing the risk of system failures caused by connector failures and extending the overall service life of the robot controller.

Antek has a professional certification team with strong certification capabilities. We are familiar with various global certification standards such as CE, FCC, ROHS, etc. From the product design stage, planning is carried out in accordance with the corresponding certification standards to ensure that the product meets the requirements in multiple aspects such as function, safety, and environmental protection. With rich certification experience and efficient communication and coordination capabilities, we can quickly promote the certification process, shorten the product launch cycle, help customers quickly obtain market access qualifications, and enhance the competitiveness of products in domestic and foreign markets.